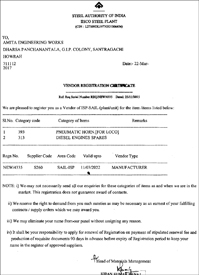

C2 or C2W Relay Valve

8000 INR/Piece

Product Details:

- Color Grey

- Type Relay Valve

- Hardness Rigid

- Finish Plain

- Surface Polished

- Click to View more

X

C2 or C2W Relay Valve Price And Quantity

- 8000 INR/Piece

- 100 Piece

C2 or C2W Relay Valve Product Specifications

- Grey

- Rigid

- Polished

- Plain

- Relay Valve

C2 or C2W Relay Valve Trade Information

- Cash Against Delivery (CAD)

- 100 Piece Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- wooden box

- All India

- iso

Product Description

C2W Relay Valve For Locomotive

The C2W Relay Air Valve is a diaphragm cooperated self lapping valve having higher capacity which is used as a remote controlled pneumatic device to relay a large quantity of main air reservoir pressure to the operating system for brake application its used for railway.

The C2W Relay Air Valve is a diaphragm cooperated self lapping valve having higher capacity which is used as a remote controlled pneumatic device to relay a large quantity of main air reservoir pressure to the operating system for brake application its used for railway.

High-Performance Relay Valve

Our C2/C2W Relay Valves deliver reliable performance for air brake systems, thanks to their rigid construction and polished, plain surface. The grey finish not only adds a professional look but also boosts corrosion resistance, making these valves ideal for long-term use in commercial vehicles.

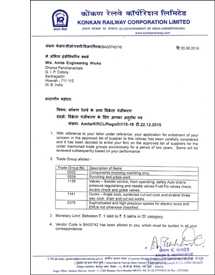

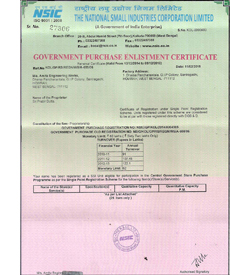

Manufactured and Exported from India

Produced by leading manufacturers, exporters, and suppliers in India, these relay valves comply with international standards. Rigorous quality checks ensure each unit meets the required specifications for hardness, finish, and functionality.

FAQs of C2 or C2W Relay Valve:

Q: How is the C2 or C2W Relay Valve used in vehicle braking systems?

A: The C2 or C2W Relay Valve is integrated into air brake systems to quickly transmit air pressure, helping activate the brakes more efficiently and ensuring prompt stopping power in commercial vehicles.Q: What are the key benefits of choosing a rigid grey, polished relay valve?

A: Selecting a relay valve with rigid structure and polished, plain surface offers enhanced durability, reduced wear, and increased resistance to environmental factors, resulting in a longer service life and improved braking performance.Q: When should the C2/C2W Relay Valve be replaced or serviced?

A: It is recommended to inspect the relay valve during routine brake maintenance. Replacement or servicing is advised when there is noticeable brake lag, air leaks, or when the valve shows signs of damage or excessive corrosion.Q: Where are these relay valves typically manufactured and supplied from?

A: C2 and C2W Relay Valves are primarily manufactured, exported, and supplied by reputed companies in India. These firms serve both domestic and international markets with high-quality products.Q: What is the manufacturing process involved in creating a relay valve with a plain finish?

A: The manufacturing process involves precision casting, machining, and polishing of high-grade materials. Quality controls ensure a plain, polished finish with a rigid structure and uniform hardness for reliable operation.Q: How does the relay valve improve overall brake system efficiency?

A: The relay valve accelerates air flow to the brake chambers, minimizing response time and offering improved braking force. This translates to safer operation and enhanced vehicle control, especially under heavy loads.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Locomotive Spare Parts' category

|

AMITA ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese